Klepáč production services

If you entrust the production in our hands, you can be sure that it will be taken care of by a staff with a lot of experience in the field and we will try to meet your wishes as much as possible.

The main operations we are able to perform are described below. If you are not sure whether we are able to produce your request, write to us. We will try to answer you as soon as possible, if possible with a quote.

Technical preparation of the production

Preparation of drawings, programs and technological procedures before entering the part into production.

Machining

We are a company that mainly deals with machining, with which we have extensive experience. We focus on machining smaller and medium-sized parts.

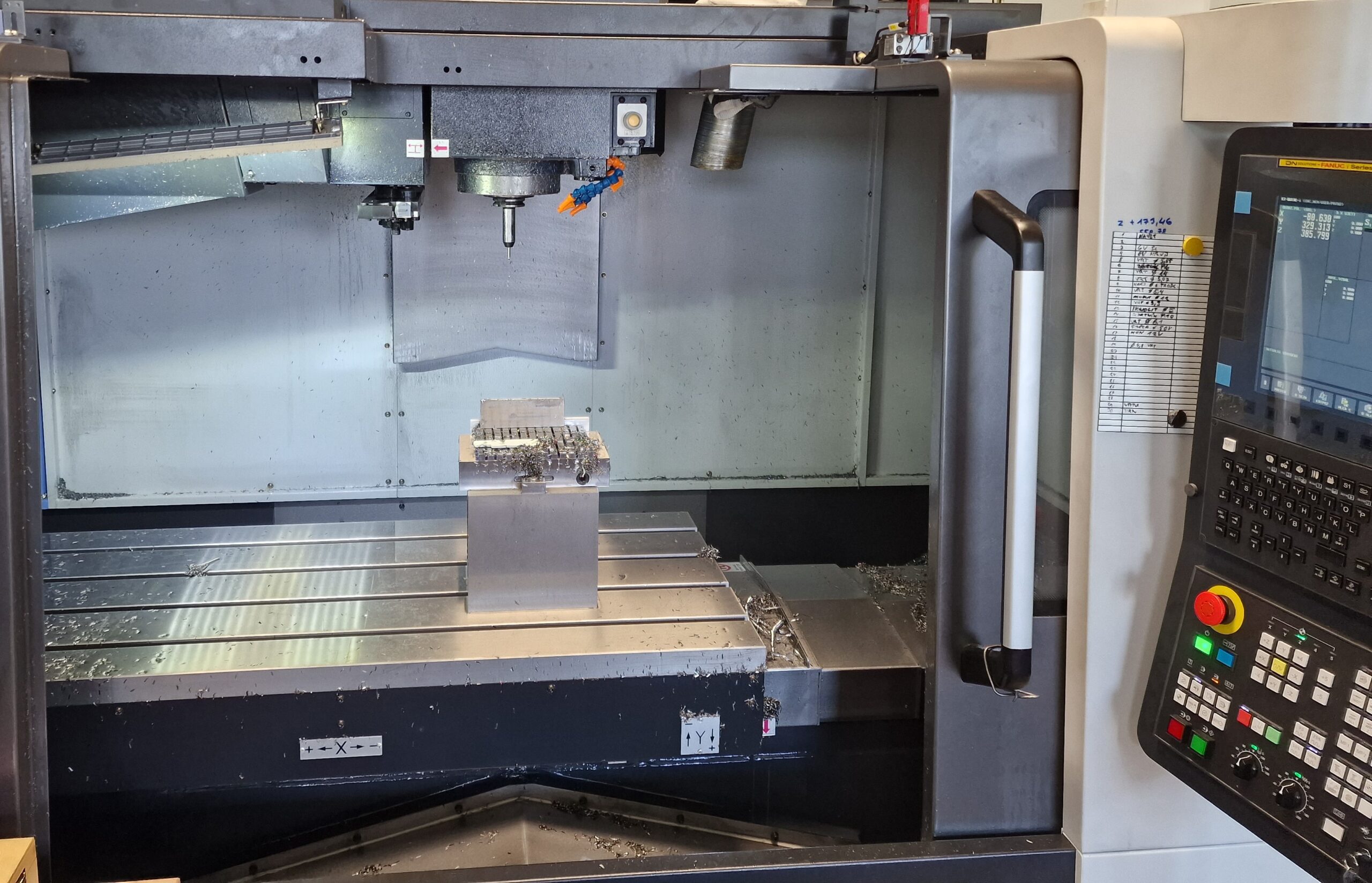

CNC machining

We have several CNC machines on which we are able to ensure the production of various parts.

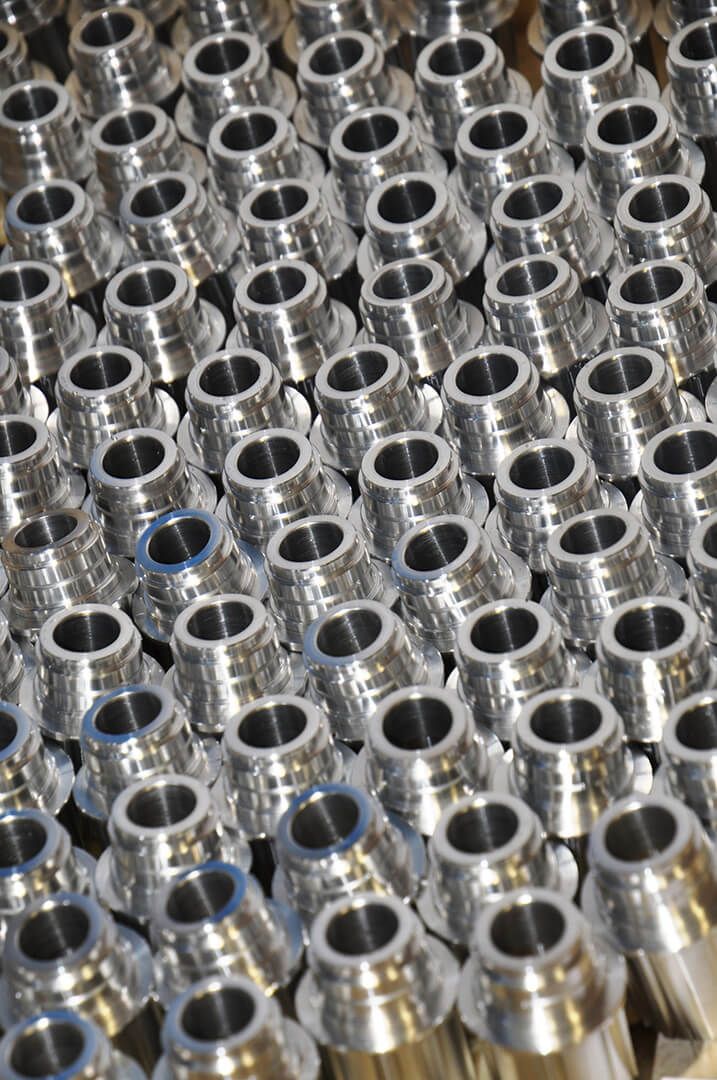

CNC turning

We are able to ensure the production of precise turned and turn-milled parts.

The maximum diameter is 350 mm and the length is 1.5 m

CNC milling

We are able to offer precise milling of parts. We also have equipment for multi-axis milling.

The maximum dimensions of the part are 750 x 500 x 500 mm.

3D measurement

We have a modern measuring room including 3D measurement machine with 400 x 400 x 300mm gauges.

CNC Turning and CNC Milling

We offer custom CNC turning and milling. We are able to machine most materials. We mainly focus on softer materials such as duralumin, brass and copper. But we are able to machine iron and other materials. For smaller series, we also have the option of manual turning and milling.

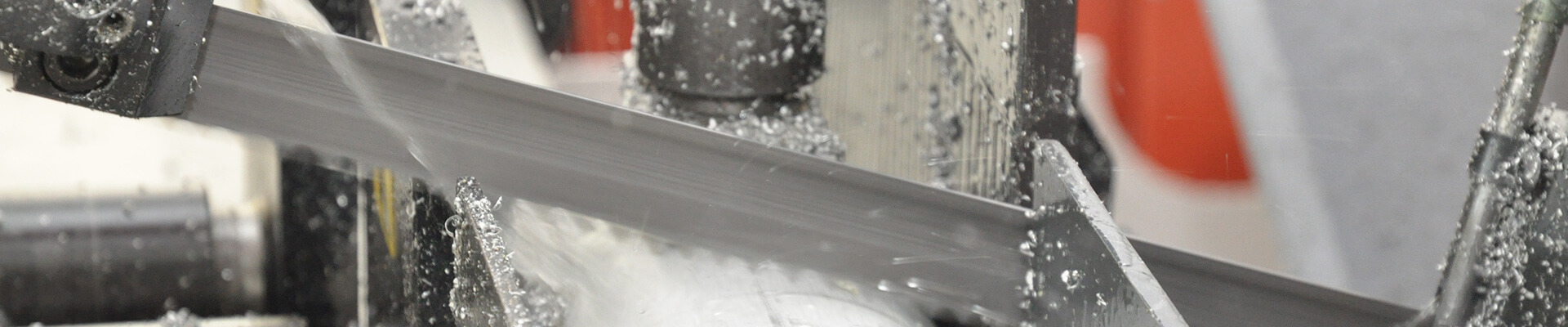

Cutting

We offer cutting of rod-shaped materials such as plastics and metals. We have an automatic band saw with a feeder and a manual band saw available. This allows us to cut both small and large series.

Construction

Thanks to our new premises, we can also arrange and organize assembly. We are able to construct an automatic machine or mediate manual assembly. It depends on the customer’s wishes and the required production volume.

We have been producing bicycle parts for the following companies for a long time: kpreadytoroll and cabtech.

Frequently asked questions about CNC and NC

What is CNC machining

CNC machining is the most common manufacturing process due to the productivity, precision and versatility it offers. It is a manufacturing process in which material is removed using tools as opposed to various additive manufacturing processes. Machining is divided into several processes such as turning, milling, drilling, turning, etc. Most CNC machines are lathes, where the workpiece rotates and the tool is stationary. And milling machines, where the workpiece is stationary and the tool moves. It is possible to machine most materials and most modern machine tools already use CNC technology (Computer numerical control), where the computer controls all movements of the lathe or milling machine.

What is a CNC program?

It is a program with information for the machine, at what speed, at what revolutions and in what direction it should move. This program is unique to each product and is an instruction for the machine on how to proceed in the production of the part. The CNC program must always be written during initial production. But when the production is repeated, it can be enjoyed over and over again. In most cases, however, the program is improved to increase quality or efficiency with each repeated production.

What is the difference between NC and CNC machining?

The difference is between the data input which the machine reads for production. With CNC, the computer controls the machine, and with NC, a punched tag is mostly used, which the machine reads and moves accordingly and performs the necessary functions. As already clear from the description, NC technologies are mostly obsolete and are being fully replaced by CNC machining.

How does CNC work?

The CNC machine has a monitor where you can write a program or manually control the machine. All movements of the machine are made using motors, in contrast to classic machine tools, where the machine was moved manually. The main advantage of a CNC machine is its automation, when it can repeatedly produce parts without human intervention.

What does a CNC machine operator do?

CNC machines are able to work without much human intervention, but there is still a need for a machine operator who must write the CNC program, install the necessary tools in the machine, set up the machine and then check the production process. During production, the operator must check the parts that the machine produces. Replenish material and take care of machine maintenance.

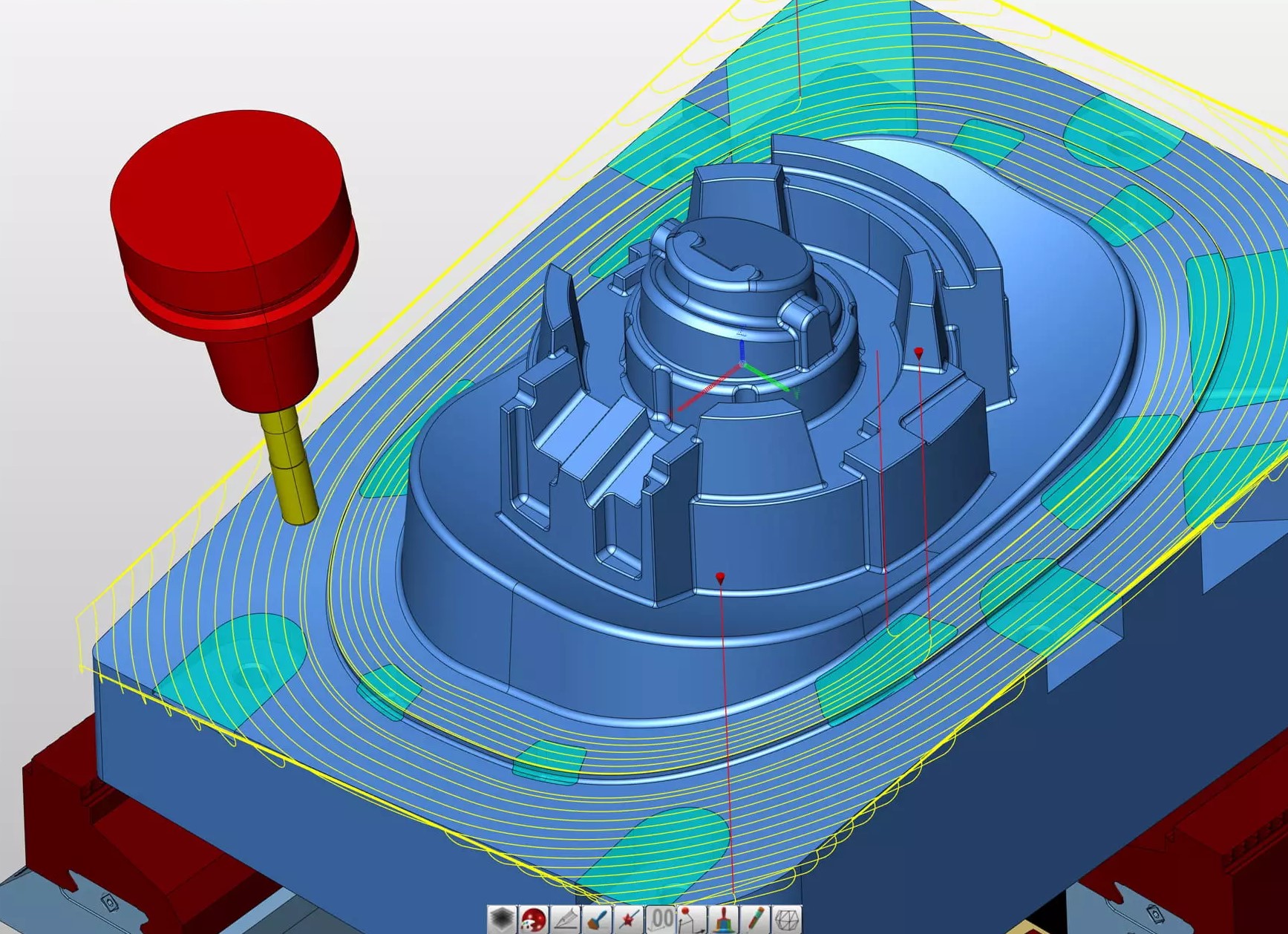

What does a CNC machine programmer do?

The programmer focuses on writing the CNC programs according to which the machine produces. It is a production preparation. Unlike the operator, the programmer usually does not deal with the adjustment of the machine and the debugging of new production. Today, CAD/CAM software is often used for programming, which is capable of writing toolpaths even for complex 3D shapes. They are also able to control the movement of several axes at once. These complex operations can no longer be programmed manually.

How to learn on a CNC machine?

CNC machine operation is a subject taught at most industrial schools. But a lot of people learned on CNC machines with a different field of study. Most companies allow training to work on CNC machines.

What is G code

It is the most commonly used programming language for CNC machines. G stands for geometry. There are several variants of G code that are more or less different from each other. It can be said that these are instructions for the machine where to move, at what speed and on what route. But far more functions can be programmed here, depending on the machine and operator. Like turning on cooling, opening CNC doors, etc.

What is a CNC milling machine

It is a machine that is used for machining. A stationary workpiece is clamped on the table and the rotating tool processes or removes material as needed. With a CNC milling machine, tool feeds and positioning are controlled by a computer, and the movement of the tool is by means of motors. In contrast to a classic milling machine, the feed and positioning are controlled manually by the operator.

What is a conventional lathe

A lathe is a machine in which a rotating workpiece is clamped. The tool is clamped stationary and removes material on the rotating workpiece. Conventional means that it is a lathe that is operated manually. There is no computer and drives to control the lathe as in a CNC machine.